Ultra Centrifugal Mill FM200

Feed size:<10mm

Final fineness:<40μm

Speed:6000-18000rpm

Share

Description

Product Video

Order Information

Product Catalogue

Operating Manual

Ultra Centrifugal Mill FM200 applies to a wide range of samples. Based on its high efficiency grinding technology and rich accessories, with two-steps grinding of rotating knife – ring screen system ,it can process dry and wet grinding in a very short time for the soft, hard, brittle, fibrous samples.

| Application |

○ Sample type:

Soft, elastic, fibrous, water-bearing, dry sample

○ Application fields:

Agriculture, environment, electronics, RoHS testing, coal, chemistry, plastics, medicine, feed, grain, dry plants, etc.

Agriculture, environment, electronics, RoHS testing, coal, chemistry, plastics, medicine, feed, grain, dry plants, etc.

Diversified application, efficient sample preparation

○Ecological environment protection: plants (root, stem and leaf, etc.) sample preparation, C.H.N determination

○Coal, coatings sample preparation; ash content, thermal measurement

○Identify the nitrogen composition and protein composition of feed and food

○Secondary fuel, rubbish, plastic, electronic elements, the determination of harmful substances

○Coal, coatings sample preparation; ash content, thermal measurement

○Identify the nitrogen composition and protein composition of feed and food

○Secondary fuel, rubbish, plastic, electronic elements, the determination of harmful substances

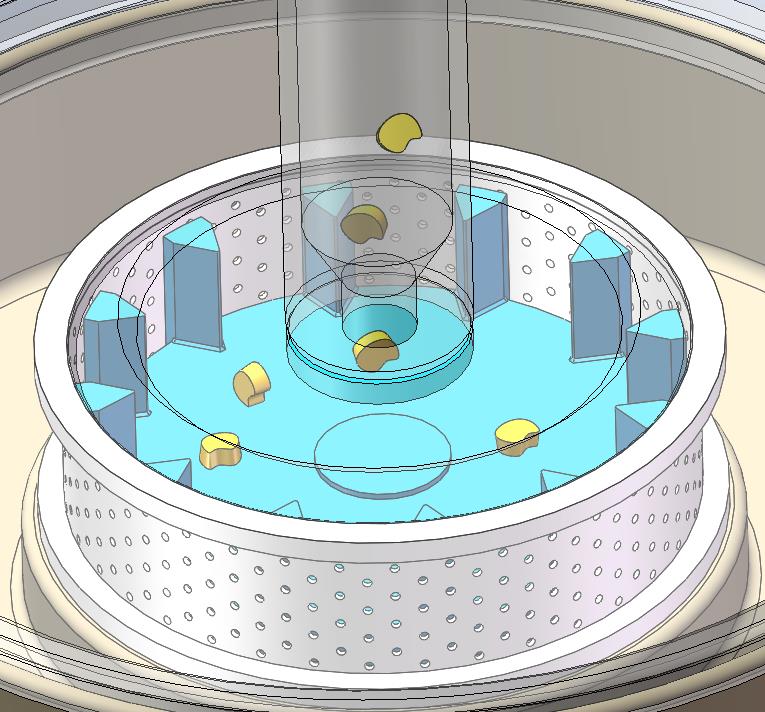

| Working Principle |

The Ultra Centrifugal Mill can realize two-stage crushing for samples with the rotor and ring sieves. Samples are fed from the hopper with anti-splashing design. Under the effect of high speed centrifugal force, the falling samples and the high speed rotor generate a giant impact force to perform pretreatment for samples; then the samples are sheared, extruded and rubbed again between the rotor and ring sieves. The sample will enter into the collecting pan when the size is less than the aperture of ring sieves. The two-stage crushing guarantees moderate and efficient grinding results. Due to the high crushing efficiency, the period of samples staying in the grinding chamber is quite short so as to avoid changes of sample natures.

| Features and advantages |

○ The final fineness less than 40μm.

○ Touch control panel, convenient and quick

○ Low noise, reliable operation, easy cleaning.

○ Rich accessories for choice ensure the application of diversification.

○ The fineness depends on the ring sieve.

○ Speed adjustable from 6000-18000rpm.

○ Two stage rotor——ring sieve system to realize quickly grinding.

○ Rotor diameter 95mm and peripheral speed up to 94.2 m/s ensure efficient grinding.

○ Touch control panel, convenient and quick

○ Low noise, reliable operation, easy cleaning.

○ Rich accessories for choice ensure the application of diversification.

○ The fineness depends on the ring sieve.

○ Speed adjustable from 6000-18000rpm.

○ Two stage rotor——ring sieve system to realize quickly grinding.

○ Rotor diameter 95mm and peripheral speed up to 94.2 m/s ensure efficient grinding.

| Technical highlights |

○ The specially designed air passage can guarantee that the grinding chamber has constant airflow to cool rotors and samples.

○ There is a double layer wear proof seal ring between the grinding chamber and the driving motor to prevent dust from entering the motor.

○ The electronic lock and the mechanical lock form double protection for operators.

○ The anti-splashing hopper can effectively prevent feedstock blocking and reduce noises.

○ Special adapters can be equipped for large-capacity collections.

○ The motor has the function of overload protection, and it continues to run after restarting due to overload.

○ There is a double layer wear proof seal ring between the grinding chamber and the driving motor to prevent dust from entering the motor.

○ The electronic lock and the mechanical lock form double protection for operators.

○ The anti-splashing hopper can effectively prevent feedstock blocking and reduce noises.

○ Special adapters can be equipped for large-capacity collections.

○ The motor has the function of overload protection, and it continues to run after restarting due to overload.

| Automatic feed device and large sample receiver |

○ Ultra Centrifugal Mill FM200 can be equipped with an automatic feed device , which can guarantee highly homogeneous grinding results and avoid the risk of sample feed overload.

○ The ground samples are collected in a collecting pan, which is convenient for collection without sample loss and prevents cross contamination of samples.

○ The ground samples are collected in a collecting pan, which is convenient for collection without sample loss and prevents cross contamination of samples.

| Technical Data | |

| Feed size | < 10mm |

| Final fineness | < 40μm |

| Speed | 6000-18000rpm |

| Peripheral speed | 31.4-94.2m/s |

| Rotor diameter | 98.5mm |

| Ring sieve | 0.08,0.12,0.20,0.25,0.50,0.75,1.00,2.00mm |

| Collecting pan volume | 900ml( volume of the sample collected no more than 300ml) |

| Rated power | 760W |

| Power supply | 220V,50/60Hz |

| Instrument size | 400*506*495mm |

| Package size | 620*620*770mm |

| Net weight | 38kg |

| Order Information-Ultra Centrifugal Mill FM200 | |

| Item No. | Description |

| Please order rotor and sieve separately | |

| 24.881.0001 | Ultra Centrifugal Mill FM200, (220 V, 50 /60Hz) incl:Labyrinth disc, stainless steel collecting pan and lid. |

| Accessories | |

| 01.865.0001 | 6 teeth rotor, stainless steel |

| 01.865.0002 | 12 teeth rotor, stainless steel |

| 01.865.0003 | 24 teeth rotor, stainless steel |

| 01.865.0006 | Collecting pan, stainless steel, incl. pan, lid of collecting pan and gasket |

| 11.865.1032 | Collecting pan with outlet, stainless steel, for cyclone |

| 01.881.0001 | Vibratory feeder VF200,incl:chute, hopper |

| 01.881.0002 | Holder,for connection between VF200 and FM200 |

| 01.865.0007 | Cyclone separator, please order collecting bottle or bucket separately |

| 70.014.0001 | Collecting bottle,250ml,1pc |

| 70.014.0002 | Collecting bottle,500ml,1pc |

| 70.014.0003 | Collecting bottle,1000ml,1pc |

| 01.865.0014 | 3L sample collecting bucket,stainless steel,for cyclone |

| 01.865.0013 | 5L sample collecting bucket,stainless steel,for cyclone |

| Ring sieves of stainless steel, with reinforced edge | |

| 02.865.0030 | trapezoid holes,0.08 mm |

| 02.865.0013 | trapezoid holes, 0.12 mm |

| 02.865.0001 | trapezoid holes, 0.2 mm |

| 02.865.0031 | trapezoid holes,0.25 mm |

| 02.865.0002 | trapezoid holes, 0.5 mm |

| 02.865.0032 | trapezoid holes,0.75 mm |

| 02.865.0003 | trapezoid holes, 1.0 mm |

| 02.865.0004 | trapezoid holes, 2.0 mm |

| 02.865.0015 | round holes,3.0mm |

| 02.865.0016 | round holes,4.0mm |

| 02.865.0017 | round holes,5.0mm |

| 02.865.0018 | round holes,6.0mm |

| for grinding without heavy-metal contamination | |

| 01.865.0005 | rotor, 12teeth, titanium |

| 01.865.0008 | Collecting pan(titanium coated) and lid (POM) with gasket |

| 03.865.0001 | Gasket for pan lid. 10 pcs |

| Ring Sieves of titanium with reinforced edge | |

| 02.865.0039 | trapezoid holes,0.08 mm |

| 02.865.0019 | trapezoid holes,0.12 mm |

| 02.865.0006 | trapezoid holes, 0.2 mm |

| 02.865.0034 | trapezoid holes,0.25 mm |

| 02.865.0007 | trapezoid holes, 0.5 mm |

| 02.865.0033 | trapezoid holes,0.75 mm |

| 02.865.0008 | trapezoid holes, 1.0 mm |

| 02.865.0020 | trapezoid holes,2.0 mm |