Sample type: hard, soft, brittle and pasty samples.

Typical sample: Soils ,chemical products,medicinal herbs,yeast cell ,cocoa ,food ,grain ,oil ,fruit,salt slag,silicate glass ceramic and cement clinker

|

Working principle |

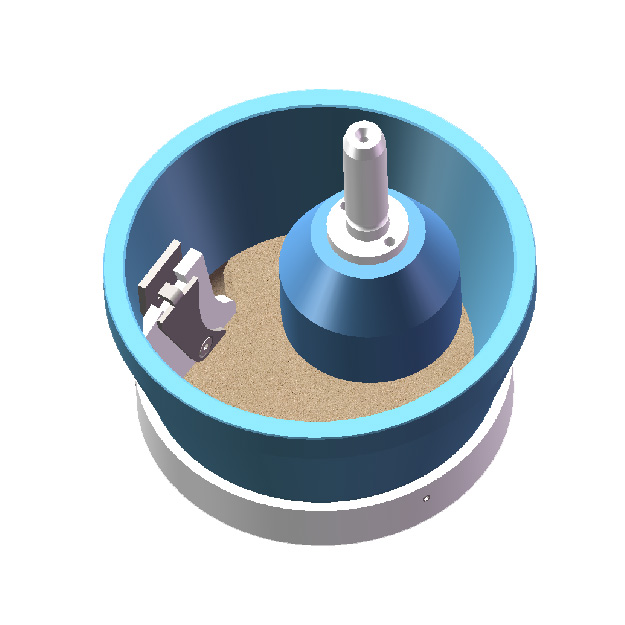

The sample enters the grinding area between the pestle and mortar via hopper and is crushed by pressure and friction.The function of the scraper is to feed the material into the area between the mortar and pestle. This forced feed ensures that the whole sample is continuously subjected to the grinding and is also intensively mixed.

| Features and advantage |

Easy to clean

- Easy exchange of mortar and pestle without tools after grinding and it' s easy to clean the mill.

Easy and safe to operate

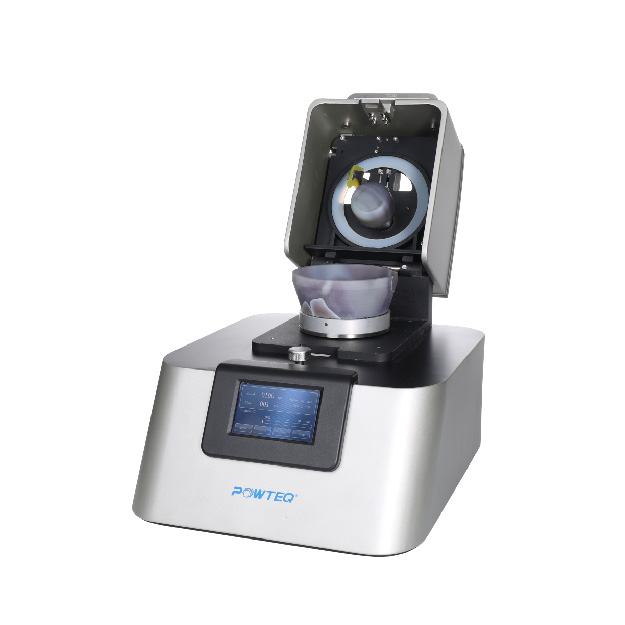

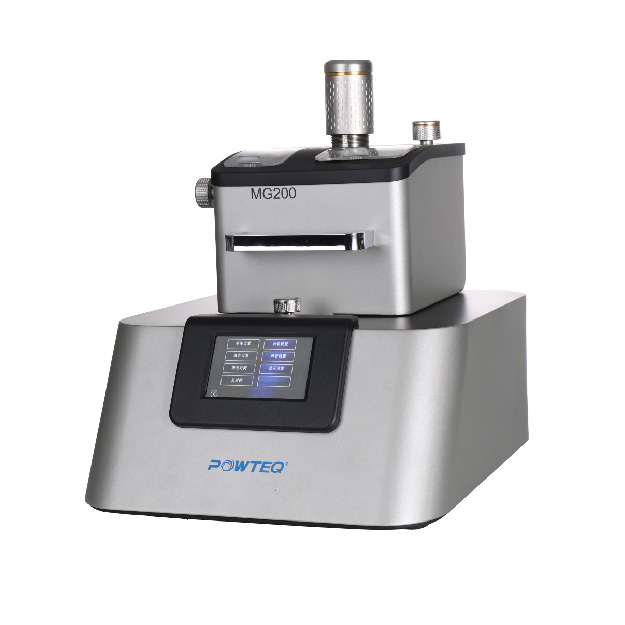

- The machine case and lid are made of hard alloy.

- lt is easy to operate and ergonomically designed.

- The grinder is equipped with magnetic switch to judge whether the lid is closed or not, and the grinder only starts when lid is closed.

- LED will light up when the observation window opened for easy observation of sample grinding process.

Suitable for dry,wet & cryogenic grinding.

Pretreatment for some rough samples.

Adding samples through the filling opening during the operation.

A variety of scraper materials are available (polyurethane, PTFE, beech wood) to meet all application requirements.

|

Skills to achieve the best grinding effect |

Before preparing the paste samples, firstly you can put the mortar and sample (eg cocoa) intot drying oven and heat to 40°C.

In the preparation of chemicals and pharmaceuticals, please add grinding aid to prevent caking phenomenon.

* It's difficult to process some samples such as yeast cells. You' d better freeze the sample with liquid nitrogen to make them more brittle and easy to mill.

Mortar and pestle

|

Technical data |

|

Feed size |

≥10mm (depending on the sample property) |

|

Final fineness |

≤5μm (depending on the sample property) |

|

Speed |

50~130rpm |

|

Batch quantity |

10~200ml |

|

Time setting |

00:01~99:59(hr/min) |

|

Display |

LED 5 inch control panel |

|

Rated power |

230W |

|

Power supply |

220V,50/60 Hz |

|

Nstrument size(W*D*H) |

400 * 480 * 500毫米 |

|

Package size(W*D*H) |

600 * 600 * 610毫米 |

|

Net weight |

41 kg |