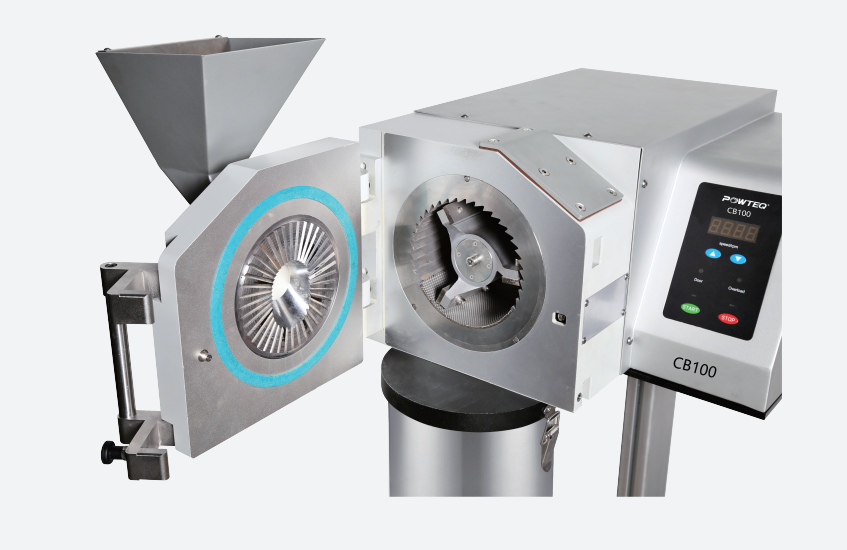

Cross Beater Mill CB100

Feed size:≤25mm

Final fineness:0.1-20mm

Speed:500-4000rpm

Cross Beater Mill CB100 is suitable for mid-hard,brittle materials. It can be used for batch processing and continuous coarse crushing and fine crushing.

| Application |

CB100 can deal with the mid-hard, brittle materials (hardness no more than 6Mohs), such as ore, coke, minerals, ceramics, slag, gravel, soil, cement, etc.

|

| Working principIe |

| CB100 grinds the samples through beating,impacting. The sample enters the center of the chamber through the hopper. The sample is crushed between the impact plate and the gear of the embedded parts. Once the sample size is smaller than the pore size of the sieve, they will enter into the receiving container. The beater rotor draws a large amount of air through the hopper channel, thus accelerate the speed of the crushed sample departing from the crushing chamber. |  |

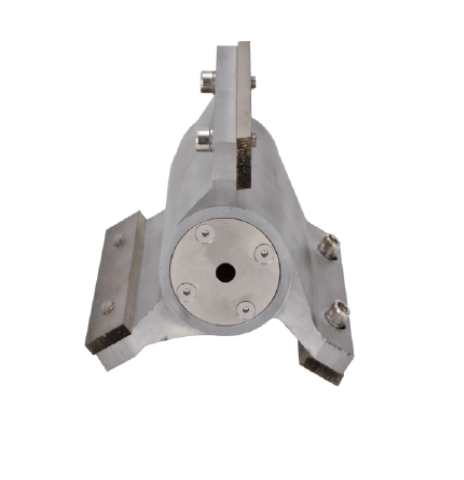

Rotor for Cross Beater Mill CB100, mainly used for crushing soil, coal, slag, glass,etc

|

We also provide rotors and sieves made of special material for heavy-metal-free crushing. |

| Features and advantages |

○ It can be fixed on the floor and equipped with casters to move easily.

○ With quick locking device and motor braking, it has high safety performance.

○ The grinding process is rapid and produces less heat.

○ The size of the sample is controlled by the bottom sieve and sieve with different sizes can be selected.

○ A large amount of sample can be processed continuously, ranging from a few kilograms to several hundred kilograms per hour.

○ CB100 can be equipped with small sample receiver and cyclone separator, which is convenient for sample collection, chamber cleaning and heat generation reduction.

○ It can feed automatically by connecting a vibratory feeder VF200.

○ Easy cleaning thanks to exchangeable push-fit grinding sieve, rotor

| Connect cyclone separator, small volume sample receiver |

| When CB100 is used with a cyclone separator, it is suitable for handling light or small volume samples. The use of cyclone separator extends the applications of the Cross Beater Mill. It not only effectively solves the heat transfer problem during the grinding process so as to make cleaning easily, but also improve the uniformity and reproducibility of the grinding results. |  |

| TechnicaI data |

|

Feed size |

≤25mm | Grinding chamber material | stainless steel, 1.1740 steel, hardened steel |

| Final fineness |

0.1-20mm |

Rated power |

1.5KW |

|

Speed |

500-4000rpm |

Power supply |

220V,50/60Hz |

|

Collector capacity |

0.25-30L |

Instrument size |

590*705*1260mm |

| Collector |

0.25L、0.5L、1L、3L、5L、30L |

Package size |

1000*1000*1450mm |

| Peripheral speed |

3.6-28.9m/s |

Net weight | 120kg |

| Sieves |

0.20/0.25/0.50/1.00/2.00/4.0/6.0/8.0/10.0/20.0mm |

| Order Information-Cross Beater Mill CB100 | |

| Item No. | Description |

| 24.961.0001 | Cross Beater Mill CB100,220V,50/60Hz, stainless steel grinding chamber |

| Accessaries CB100 | |

| 02.885.0007 | rotor with stainless steel blades |

| 02.885.0008 | rotor with hardened steel blades |

| 02.885.0009 | rotor with 1.1740steel blades |

| 11.885.1074 | cross beater blade,stainless steel. Minimum order quantity:3pcs |

| 11.885.1026 | cross beater blade,hardened steel. Minimum order quantity:3pcs |

| 11.885.1060 | cross beater blade,1.1740steel. Minimum order quantity:3pcs |

| Bottom sieve CB100 | |

| 02.885.0027 | stainless steel, 0.12mm, trapezoid holes |

| 02.885.0010 | stainless steel, 0.2mm,trapezoid holes |

| 02.885.0028 | stainless steel, 0.25mm,trapezoid holes |

| 02.885.0011 | stainless steel, 0.5mm,trapezoid holes |

| 02.885.0029 | stainless steel, 0.75mm,trapezoid holes |

| 02.885.0012 | stainless steel, 1.0mm,trapezoid holes |

| 02.885.0035 | stainless steel, 2.0mm,trapezoid holes |

| 02.885.0052 | stainless steel, 3.0mm,round holes |

| 02.885.0014 | stainless steel, 4.0mm,round holes |

| 02.885.0053 | stainless steel, 5.0mm,round holes |

| 02.885.0015 | stainless steel, 6.0mm,round holes |

| 02.885.0016 | stainless steel, 8.0mm,round holes |

| 02.885.0017 | stainless steel, 10.0mm,round holes |

| Bottom sieve CB100,without heavy metal contamination | |

| 02.885.0036 | steel without heavy metal contamination, 0.12mm,trapezoid holes |

| 02.885.0018 | steel without heavy metal contamination, 0.2mm,trapezoid holes |

| 02.885.0037 | steel without heavy metal contamination, 0.25mm,trapezoid holes |

| 02.885.0019 | steel without heavy metal contamination, 0.5mm,trapezoid holes |

| 02.885.0038 | steel without heavy metal contamination, 0.75mm,trapezoid holes |

| 02.885.0020 | steel without heavy metal contamination, 1.0mm,trapezoid holes |

| 02.885.0039 | steel without heavy metal contamination, 2.0mm,trapezoid holes |