Rotor Beater Mill CR200

Feed size:≤25mm

Final fineness:40μm-10mm

Speed:3000-10000rpm

Rotor Beater Mill CR200 can grind soft and hard materials by impact and shear action to achieve grinding effect.

| Typical samples |

pharmaceutical products, seeds, building materials, soil, chemicals, medicines, fertilizers, feed granules, grains, spices, coal, etc

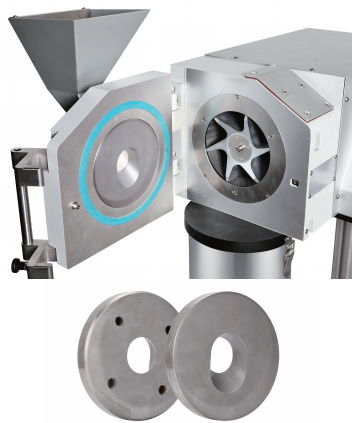

| Working principIe |

| Sample enters the center of grinding chamber through the hopper, and was crushed between the rotor, sieve by impact and shear effects.Once the sampe size if samller than the apterture size of the sieve, they will enter into the receivning container. The quick locking design of the mill door ensures convenient cleaning of and fast access to the grinding chamber. |  |

| Accessories |

|

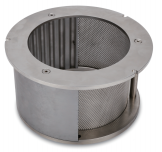

180° bottom sieves:suitable for soft, medium hard shell grain samples |

|

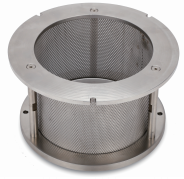

360°bottom sieves:suitable for soft and brittle grain samples |

|

Rotor for CR200:mainly used for crushing grain,for example:wheat,corn,soybean. |

| Features and advantages |

○Adjustable speed of 3,000-10,000RPM to suit different application requirements

○The maximum feed size is 25 mm

○Final fineness d 90 < 50 µm

○180 degree sieve suitable for hard samples, such as grain with shell

○360 degree sieve suitable for medium-hare, ductile and fibrous samples

○Defined final fineness due to sieves with aperture size from 0.08-10.0mm

○Strong airflow due to high rotational speed can quickly cool the sample and facilitate sample collection and cleaning of grinding chamber

○Easy cleaning thanks to exchangeable push-fit grinding sieve, rotor

| Connect cyclone separator, small volume sample receiver |

| When CR200 is used with a cyclone separator, it is suitable for handling light or small volume samples. The use of cyclone separator extends the applications of the Rotor Beater Mill. It not only effectively solves the heat transfer problem during the grinding process so as to make cleaning easily, but also improve the uniformity and reproducibility of the grinding results. |

| TechnicaI data |

|

Feed size |

≤25mm | Grinding chamber material | stainless steel, 1.1740 steel, hardened steel |

| Final fineness |

40μm-10mm |

Rated power |

3.7KW |

|

Speed |

3000-10000rpm |

Power supply |

380V,50/60Hz |

|

Collector capacity |

0.25-30L |

Instrument size |

590*705*1260mm |

| Collector |

0.25L、0.5L、1L、3L、5L、30L |

Package size |

1000*1000*1450mm |

| Peripheral speed |

21.4-71.2m/s |

Net weight | 120kg |

| Sieves |

0.08/0.20/0.25/0.50/1.00/2.00/4.0/6.0/8.0/10.0mm |

| Order Information-Rotor Beater Mill CR200 | |

| Item No. | Description |

| 24.914.0001 | Rotor Beater Mill CR200 ,380V, 50/60Hz, 3000-10000RPM,3.7KW,including rotor, 5L collecting bucket, stand frame |

| Rotor | |

| 03.885.0005 | rotor,stainless steel |

| Retaining frame | |

| 03.885.1003 | retaining frame,360°, stainless steel |

| 03.885.1001 | retaining frame,180°, stainless steel |

| Sieves | |

| 03.885.0047 | 360° of stainless steel 0.08mm,trapezoid holes |

| 03.885.0048 | 360° of stainless steel 0.12mm,trapezoid holes |

| 03.885.0007 | 360° of stainless steel 0.20mm,trapezoid holes |

| 03.885.0049 | 360° of stainless steel 0.25mm,trapezoid holes |

| 03.885.0008 | 360° of stainless steel 0.5mm,trapezoid holes |

| 03.885.0050 | 360° of stainless steel 0.75mm,trapezoid holes |

| 03.885.0009 | 360° of stainless steel 1.0mm,trapezoid holes |

| 03.885.0040 | 360° of stainless steel 2.0mm,trapezoid holes |

| 03.885.0051 | 360° of stainless steel 3.0mm,round holes |

| 03.885.0011 | 360° of stainless steel 4.0mm,round holes |

| 03.885.0014 | 360° of stainless steel 10.0mm,round holes |

| 03.885.0052 | 180° of stainless steel 0.08mm,trapezoid holes |

| 03.885.0053 | 180° of stainless steel 0.12mm,trapezoid holes |

| 03.885.0022 | 180° of stainless steel 0.20mm,trapezoid holes |

| 03.885.0054 | 180° of stainless steel 0.25mm,trapezoid holes |

| 03.885.0023 | 180° of stainless steel 0.50mm,trapezoid holes |

| 03.885.0055 | 180° of stainless steel 0.75mm,trapezoid holes |

| 03.885.0024 | 180° of stainless steel 1.0mm,trapezoid holes |

| 03.885.0025 | 180° of stainless steel 2.0mm,trapezoid holes |

| 03.885.0056 | 180° of stainless steel 3.0mm,round holes |

| 03.885.0026 | 180° of stainless steel 4.0mm,round holes |

| 03.885.0029 | 180° of stainless steel 10.0mm,round holes |