Vibratory Disc Mill VM3

Feed size:<15mm

Final fineness:<20μm

Speed:700~1500rpm

Vibratory Disc Mill is mainly used for sample preparation of spectral analysis. The device is especially suitable for fast medium-hard, brittle and fibrous materials to analytical fineness grinding without loss.

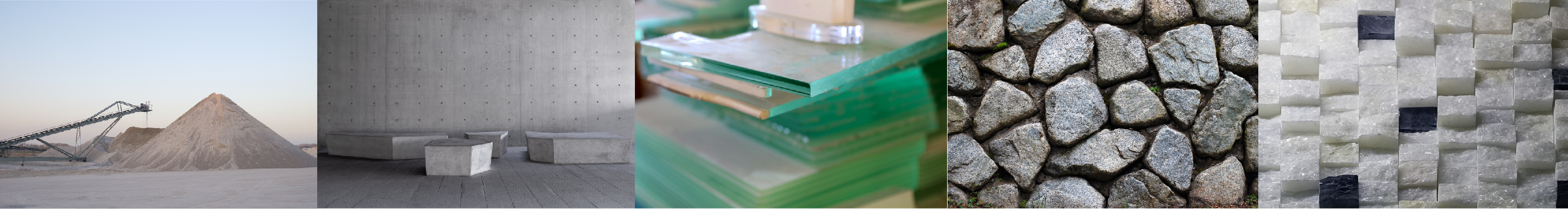

| Applications |

○ Ceramics and glass: oxide ceramics,glass

○ Building materials:cement, stone, concrete

○ Environmental area: soil, paving stone, slag

○ Minerals & Metallurgy:coal, coke, corundum, ore, slag

| Working principle |

Vibratory Disc Mill crush sample via pressure, impact and friction. The quick-action clamping device makes the grinding set firmly attached onto the vibrating plate. Through transmission, the vibrating plate will generate drastic three dimensional vibrating so as to produce giant impacting, frictional and grinding force on the grinding set, and such forces focus on samples to make them become powder in a very short time.

| Features and advantages |

○ Extremely short grinding time.

○ Final fineness(<20μm).

○ Speed 700-1500rpm, continuous adjustable.

○ Quick-action clamping device for grinding set.

○ Different kinds of materials of grinding sets for choice.

○ Agate recognition for automatic speed reduction to 700rpm.

| Technical Data |

| Feed size | <15mm |

| Final fineness | <20μm |

| Speed | 700~1500rpm |

| Time setting | 00:01-99:59 (min/s) |

| Batch quantity | 20-250g |

| The volume of the grinding set | 50ml、100ml、250ml |

| Grinding set material | hardened steel、tungsten carbide、agate(speed 700rpm)、zirconium oxide、steel 1.1740 |

| Rated power | 1.5KW |

| Power supply | 220V, 50Hz/60Hz |

| Instrument size(W*D*H) | 800*690*1255mm |

| Package size(W*D*H) | 1130*1030*1470mm |

| Weight | 277Kg |

* Information on this site is provided for information purposes only and the contents hereof are subject to change without notice.

| Order Information-Vibratory Disc Mill VM3 | |

| Item No. | Description |

| on wheels (please order grinding set separately) | |

| 24.880.0001 | Vibratory Disc Mill VM3, 220V, 50/60Hz |

| VM3 grinding set | |

| 02.880.0116 | hardened steel 50ml |

| 02.880.0101 | hardened steel 100 ml |

| 02.880.0102 | hardened steel 250 ml |

| 02.880.0113 | agate 50ml (only for 700rpm) |

| 02.880.0107 | agate 100ml (only for 700rpm) |

| 02.880.0105 | zirconium oxide 50ml |

| 02.880.0106 | zirconium oxide 100ml |

| 02.880.0103 | tungsten carbide 100ml (only for 1200rpm) |

| 02.880.0104 | tungsten carbide 250ml (only for 1200rpm) |

| 02.880.0114 | tungsten carbide 50ml(only for 1200rpm) |

| 02.880.0110 | stainless steel 100ml |

| 02.880.0111 | stainless steel 250ml |

| 02.880.0112 | stainless steel 50ml |

| for grinding without heavy-metal contamination | |

| 02.880.0108 | steel 1.1740 100ml |

| 02.880.0109 | steel 1.1740 250ml |

| 02.880.0115 | steel 1.1740 50ml |

| Accessories VM3 | |

| 70.011.0046 | O-ring for 100ml stainless steel/hardened steel/1.1740 steel grinding sets |

| 70.011.0041 | O-ring for 100 ml agate/zirconium oxide grinding sets(small) |

| 70.011.0042 | O-ring for 100 ml agate/zirconium oxide grinding sets(big) |

| 70.011.0043 | O-ring for 100 ml tungsten carbide grinding sets(small) |

| 70.011.0044 | O-ring for 100 ml tungsten carbide grinding sets(big) |

| 70.011.0045 | O-ring for 250ml stainless steel/ hardened steel/1.1740 steel grinding sets |

| 70.011.0035 | O-ring for 250 ml tungsten carbide grinding sets(small) |

| 70.011.0040 | O-ring for 250 ml tungsten carbide grinding sets(big) |

| For grinding set with agate/zirconium oxide/tungsten carbide material, a small and a big O-ring should be used at the same time. | |