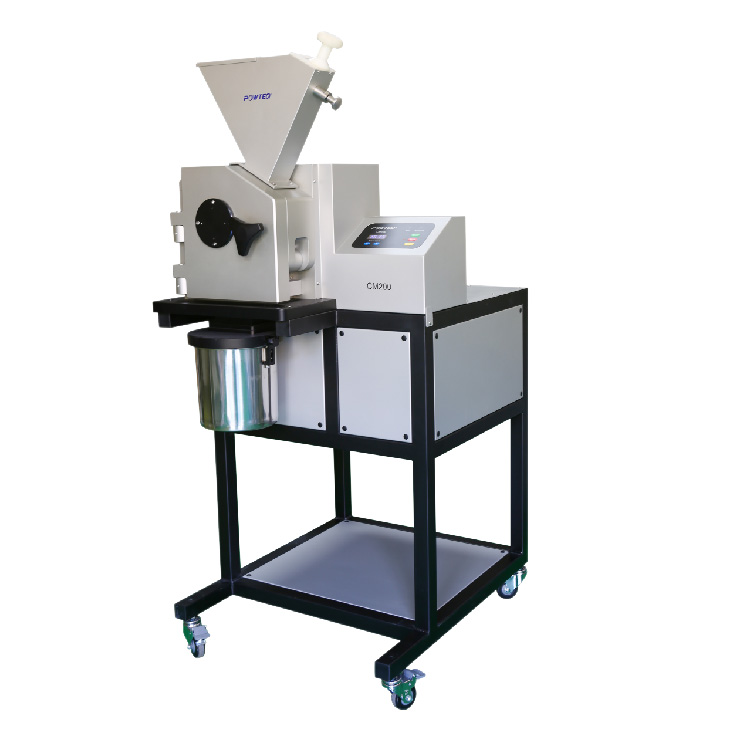

Cutting Mill CM200

Feed size:<60*80mm

Final fineness:0.1-20mm

Time setting:0~999min

CM200 is an ideal machine for the sample pretreatment of heavy-metal-free RoHS and WEEE test . It is always used to process solid samples in batch or continuously, For the long fiber and big volume sample it can process directly and do not need the pre-crush.

| Application |

| Working Principle |

The cutting mill processes the sample by the strong cutting and shear force. The sample to

be processed falls into the cutting chamber via the hopper and is shredded by cutting between rotating and fixed knives until it passes an attached sieve as ground product into the collection bucket.

| Features and advantages |

○ Powerful size reduction, even of heterogeneous mixtures;

○ The speed is adjustable between 500-3000rpm,continuouslyadjustable;

○ Final fineness depends on bottom sieve;

○ Apply to the temperature sensitivity samples due to the quickly and less heat milling;

○ Wide range of collection system to meet various requirement;

○ Big screen touch panel, human interface, speed adjustment can be imported by the control panel;

○ The operation of CM series is quite simple and safe.

○ The electric safety switch can prevent the device from being started when the door is open.

○ The rotating knife, bottom sieve and hopper can be easily removed and re-installed,such designs greatly facilitate the cleaning of the grinding chamber.

|

Technical Data |

| Feed size | <60*80mm |

| Final fineness | 0.1~20mm |

| Speed | 500~3000rpm |

| Sieves | 0.20/0.5/1.00/2.00/4.00/6.00/8.00/10.00mm |

| Collector | 0.25L,0.5L,1L,2L,5L,30L |

| Rotor | 6-disc rotor、standard rotor |

| Standard | CE |

| Rated power | 3.0KW |

| Power supply | 380V,50/60Hz |

| Instrument size(W*D*H) | 640*825*1510mm |

|

Package size(W*D*H) |

1000*1000*1450mm |

|

Net weight |

186kg |

*Information on this site is provided for information purposes only and the contents hereof are subject to change without notice.

| Order Information-Cutting Mill CM200 | |

| Item No. | Description |

| 24.868.0001 | Cuttign Mill CM200,380V,50 /60Hz,Al grinding chamber, stainless steel cutting bars |

| 24.868.0004 | Cutting Mill CM200,380V,50 /60Hz, stainless steel 304 grinding chamber, stainless steel cutting bars |

| 24.868.0002 | CM200,380V, 50/60Hz,Al grinding chamber, steel 1.1740 cutting bars for grinding without heavy-metal contamination |

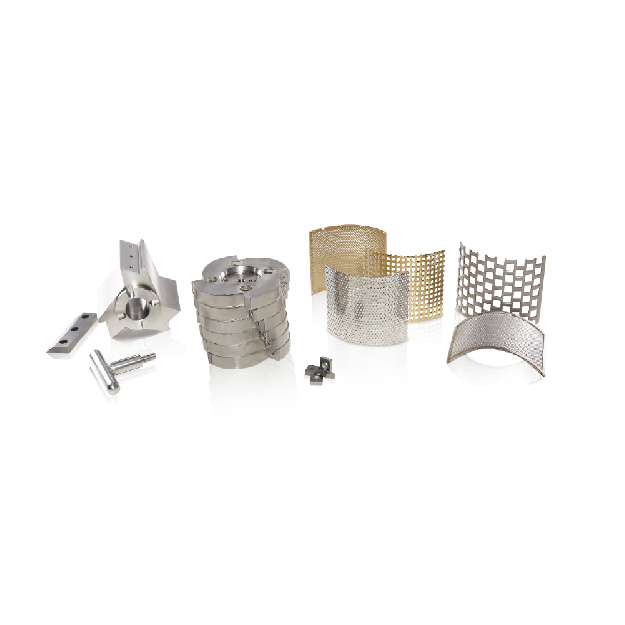

| Rotor CM200 | |

| 01.885.0003 | Standard rotor stainless steel |

| 01.885.0004 | Standard rotor stainless steel with cutting blades of steel 1.1740(without heavy-metal contamination) |

| 01.885.0005 | 6-disc rotor stainless steel |

| 01.885.0006 | 6-disc rotor stainless steel with cutting blades of tungsten carbide |

| 01.868.0003 | V type rotor, stainless steel |

| Accessories CM200 | |

| 11.868.1072 | stainless steel cutting bar(Minimum order quantity:3pcs) |

| 11.868.1073 | 1.1740 steel cutting bar(Minimum order quantity:3pcs) |

| 11.868.1069 | stainless steel cutting blades(Minimum order quantity:3pcs) |

| 11.868.1071 | 1.1740steel cutting blades(Minimum order quantity:3pcs) |

| 11.868.1063 | stainless steel cutting blades for 6-disc rotor(Minimum order quantity:24pcs) |

| 11.868.1064 | tungsten carbide cutting blades for 6-disc rotor(Minimum order quantity:24pcs) |

| Feed hopper CM200 | |

| 01.868.0001 | V type feed hopper, plain carbon steel Q235 |

| 01.885.1002 | V type feed hopper, stainless steel 316 |

| 01.885.1001 | standard feed hopper, plain carbon steel Q235 |

| Bottom sieve of stainless steel CM101/CM200 | |

| 01.885.0013 | trapezoid holes, 0.20 mm |

| 01.885.0036 | trapezoid holes,0.25mm |

| 01.885.0014 | trapezoid holes, 0.50 mm |

| 01.885.0037 | trapezoid holes,0.75mm |

| 01.885.0015 | trapezoid holes, 1.00 mm |

| 01.885.0016 | trapezoid holes, 2.00 mm |

| 01.885.0017 | square holes, 4.00 mm |

| 01.885.0018 | square holes, 6.00 mm |

| 01.885.0019 | square holes, 8.00 mm |

| 01.885.0020 | square holes, 10.00 mm |

| 01.885.0044 | square holes,20.0mm |

| Bottom sieves of steel for grinding without heavy-metal contamination CM200 | |

| 01.885.0021 | trapezoid holes, 0.20 mm |

| 01.885.0045 | trapezoid holes,0.25mm |

| 01.885.0022 | trapezoid holes, 0.50 mm |

| 01.885.0046 | trapezoid holes,0.75mm |

| 01.885.0023 | trapezoid holes, 1.00 mm |

| 01.885.0024 | trapezoid holes, 2.00 mm |

| 01.885.0025 | square holes, 4.00 mm |

| 01.885.0026 | square holes, 6.00 mm |

| 01.885.0027 | square holes, 8.00 mm |

| 01.885.0035 | square holes, 10.00 mm |

| Accessories for CM200 | |

| 04.885.0007 | Vibratory Feeder VF200(suitable for CB100/CR200) |

| 04.885.0001 | 5L sample collecting bucket,stainless steel,for main machine |

| 70.014.0016 | collecting bottle for cyclone,250ml,1pc |

| 70.014.0017 | collecting bottle for cyclone,500ml,1pc |

| 70.014.0018 | collecting bottle for cyclone,1000ml,1pc |

| 04.885.0013 | 250ml sample receiver(incl.adapter,and 2pcs collecting bottle,250ml) |

| 04.885.0014 | 500ml sample receiver(incl.adapter,and 2pcs collecting bottle,500ml) |

| 04.885.0010 | collecting bucket(stainless steel, including filter bag and connection), 5L |

| 04.885.0011 | collecting bucket(plastic, including filter bag and connection),30L |

| 04.885.0012 | Cyclone separator for light and small volume sample grinding (please order collecting bottle or bucket separately) |

| 01.865.0014 | collecting bucket,3L, stainless steel,for cyclone |

| 01.865.0013 | collecting bucket,5L,stainless steel,for cyclone |

| 11.885.1043 | Door seal ring,for CM101/CM200, 5pcs/kit |

| 11.885.1041 | Door seal ring,for CB100/CR200, 5pcs/kit |