Hammer Mill CB1000

Feed size:<5 mm

Final fineness:0.2mm

Speed:10000rpm

Hammer mill CB1000 process samples by impacting effects which suitable for brittle, mid-hard samples preparation. Also it could process large batches of coarse and fine grinding, widely used in power plants and sample preparation labs for coal quality analysis by its easy handling, efficiency and accurate mill, less residual in mill chamber as well.

| Application |

Coal, coke, soil, glass, minerals, refractory clay, oxide, porcelain, granite etc.

| Working principle |

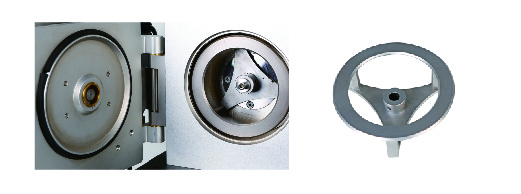

Samples are fed into the center of mill chamber through patent feeding hopper, then it impacted with cross tapping rotor moving at high speed and frequency to reduce particle size. Once the particle size is less than sieve diameter, it will fall into collecting pan. Massive air will be absorbed by the rotor through feeding tunnel which accelerate reduced particle leave mill chamber.

| Features and advantages |

○Electric braking;

○Adjustable rotate speed;

○Bench-top, easy handling, saving space;

○Auto-feeding system, reduce operational error and contamination;

○Rotors and bottom sieves separating easily, convenient to clean mill chamber;

○Controllable reduced particle size from 0.2mm to 10mm by bottom sieves diameters;

○High frequency and high rotate speed motor(10000rpm) fulfilled efficiency milling and less residual in mill chamber.

| Technical Data |

| Max feed size | <5 mm |

| Final fineness | 0.2mm |

| Speed | 10000rpm |

| Rotor peripheral velocity | 76.3 m/s |

| Rated power | 1.2KW |

*Information on this site is provided for information purposes only and the contents hereof are subject to change without notice.

| Order Information-Hammer Mill CB1000 | |

| Item No. | Description |

| 24.899.0001 | Hammer Mill CB1000 ,Incl.: host, screw type auto feeder |

| Please order mill rotor and sieve separately | |

| Accessories | |

| 11.899.1029 | Rotor, stainless steel |

| 01.899.0003 | 0.2mm sieve,stainless steel, round holes |