CryoGrinder LM200

Batch capacity:0.1-100g

pre-cooling chamber:400ml

Grinding chamber:200ml

with the rapid development of science and technology, DNA detection and polymer analysis are becoming more and more important. ln order to maintain the original components and biological information of sam- ples,it is necessary to adopt low-temperature pulverization. cryoGrinder LM200 chills the sample in liquid nitrogen and pulverize them with a magnetically driven impactor. The sample become brittle and the vola- tile components are preserved under the low temperature, so that a good grinding effect can be achieved.

The automatic control function of liquid nitrogen content avoids the contact and danger of manual operation.

| Application |

○ AppIication

lt is applied to samples with strong toughness and thermal sensitivity that are difficult to be ground and crushed at room temperature, such as rubber, plastic, food, mineral, animal and plant tissue analysis, drug, biochemical DNA detection, cell disruption and other fields.

○ TypicaI sampIe

polymers, rubber, textile materials, grain particles, hair,nails,skin, bones, muscle tissue, etc.

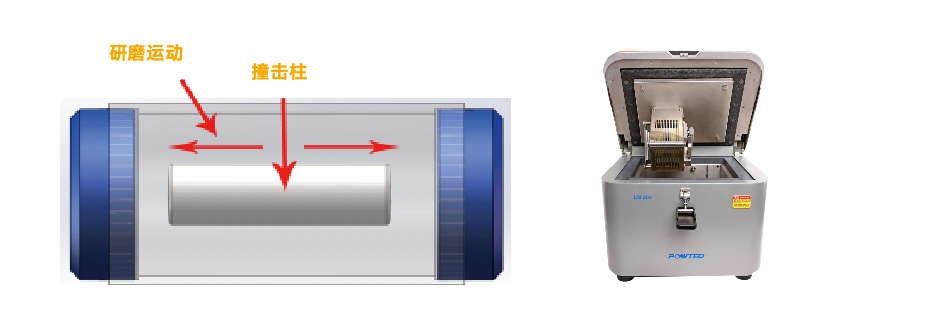

| Working principIe |

size reduction is taken place by electromagnetic oscillation impact. The sample and the metal impactor are loaded into the grinding jar together. The grinding jar is sealed with plug head by the two ends and put into the electromagnetic vibration drum coil. Electromagnetic coil with grinding jar immersed in liquid nitrogen to be pr-cooled. The whole grinding process is carried out in liquid nitrogen(-196 c). The magnetic force generated by the coil drives the impactor to move horizontally, thus continu- ously impact on then grind the sample that has been frozen and

embrittled.

| Features and advantages |

O Electromagnetic vibration impact guarantees fast grinding speed, high precision, good uniformity and

repeatability;

O The liquid nitrogen automatic filling system automatically supplement the liquid nitrogen consumed in

the process of sample freezing and grinding to ensure the stability and safety;

O lndustrial touch screen control panel, impact frequency, pre-cooling time, impact grinding time, cycle

grinding times can be set, easy to operate and reliable;

O safety design: when the cover of the instrument is open, the instrument cannot be started; only when

the instrument cover is closed and locked can the instrument be started;

Ostreamlined and ergonomic design, simple and convenient operation;

O When the liquid nitrogen level is lower than the set value, the liquid sensor will alarm and automatically replenish the liquid nitrogen; and the instrument stops running to protect the electromagnetic coil fromdamage.

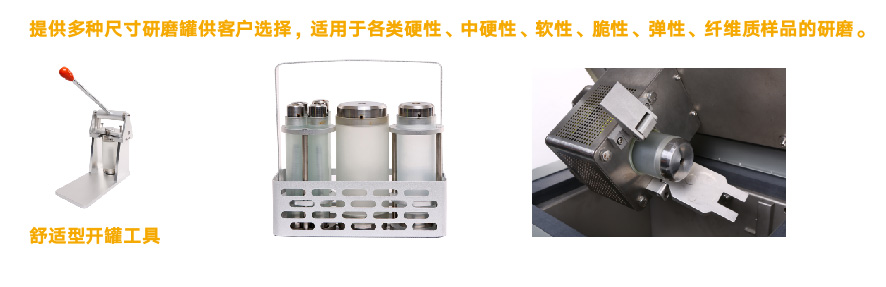

O Various specifications of grinding jar and impactor, suitabIe for a wider range of appIications

O provide different size grinding jars, satisfy the requirement of hard, medium hard, soft, brittle, elastic,

fiber samples grinding.

O To achieve better grinding effect, the appropriate size of grinding jar should be selected according to

the amount of the grinding sample. lt is suggested that the sample filling amount should be 5%-25% of

the volume of the grinding jar (depending on different sample characteristics) .

| TechnicaI data |

|

single grinding time |

2min |

Liquid nitrogen filling system |

Manual/automatic optional |

|

The shortest pre-cooling time |

4.5min |

lmpact frequency |

5-15Hz |

|

Batch capacity |

0.1-100g |

Rated power/power supply |

1.9KW/220V,50/60Hz |

|

pre-cooling chamber |

400ml |

lnstrument size |

510*440*450mm |

| Grinding chamber |

200ml |

package size |

870*720*750mm |

| Grinding jars |

4groups(4x3二12pieces)jars of 3ml/4 jars of 20ml /one jar of 100ml/one jar of 200m |