Ultra Centrifugal Mill FM300

Feed size:<10mm

Final fineness:<40μm

Speed:6000-23000rpm

Ultra Centrifugal Mill FM300 applies to a wide range of samples. Based on its high efficiency grinding technology and rich accessories, with two-steps grinding of rotating knife – ring screen system ,it can process dry and wet grinding in a very short time for the soft, hard, brittle, fibrous samples.

| Application |

○ Sample type:

Soft, elastic, fibrous, water-bearing, dry sample

Agriculture, environment, soil, electronics, RoHS testing,coal, chemistry, plastics, medicine, feed, grain, dry plants,etc.

| Diversified application, efficient sample preparation |

○ Ecological environment protection: plants (root, stem and leaf, etc.) sample preparation, C.H.N determination

○ Identify the nitrogen composition and protein composition of feed and food

○ Secondary fuel, rubbish, plastic, electronic elements, the determination of harmful substances

| The grinding art for special samples |

○ Plastic and rubber samples will become brittle and easy to grind in liquid nitrogen condition.

○ The distance ring sieve and automatic vibratory feeder can be used for grinding heat-sensitive samples such as paint, resin.

○ The rotor and ring sieve with wear-resisting coatings can be used for grinding rigid and corrosive materials such as fertilizers,chemicals.

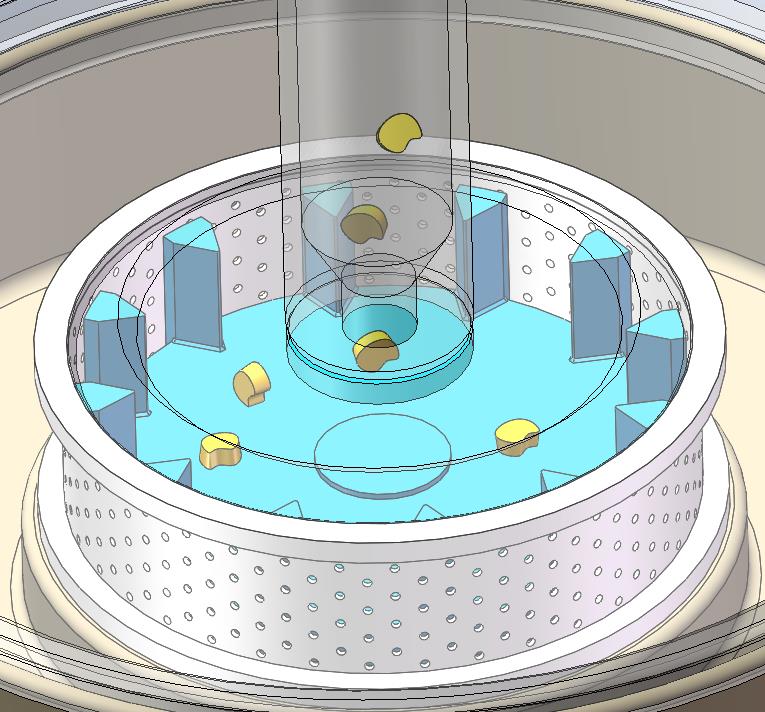

| Working Principle |

| Features and advantages |

○ Touch control panel, convenient and easy to operate.

○ Low noise, reliable operation, easy cleaning.

○ Rich accessories for option enable various application.

○ Speed adjustable from 6000-23000rpm.

○ Different fineness can be realized by selection of ring sieves with different aperture size.

○ Rotor-ring sieve two stage grinding system ensures reliable grinding result.

○ Rotor diameter 99mm and peripheral speed up to 119 m/s ensure efficient grinding.

| Technical highlights |

○ The electronic lock and the mechanical lock form double protection for operators.

○ The motor has the function of overload protection, and it continues to run after restarting due to overload.

| Automatic feed device and large sample receiver |

| Diversified accessories |

Spups

Final fineness depends on the different aperture ring sieve. We also provide the reinforcing screen to enhance the stability of the ring sieve.

○ The material of all the rotors and the ring sieves not only has stainless steel but also the heavy-metal-free for choice to meet different laboratory requirements.

○ The rotor and the ring sieve are chosen according to the properties of the samples, the required final fineness and subsequent analysis.

○ We offer a special ring sieve with shear function, for most materials, about 80% of the samples can reach the fineness of less than the half aperture size of the sieve used.

| Technical Data | |

| Feed size | < 10mm |

| Final fineness | < 40μm |

| Speed | 6000-23000rpm |

| Peripheral speed | 31-119m/s |

| Rotor diameter | 98.5mm |

| Ring sieve | 0.08, 0.12, 0.20, 0.25, 0.50, 0.75, 1.00, 2.00mm |

| Collecting pan volume | pan:900/1200ml; bottle or bucket: 250ml, 500ml, 1L, 3L,5L |

| Rated power | 1300W |

| Power supply | 220V,50/60Hz |

| Instrument size | 500*400*470mm |

| Package size | 590*590*630mm |

| Net weight | 38kg |